Topwellwelders Tips:Avoiding Weld Distortion on Thin Sheet

- Share

- Issue Time

- Jul 15,2016

Summary

What can we do to prevent the parts being distorted after welding?

What can we do to prevent the parts being distorted after welding?

Q: When we weld on thin sheet metal or stainless steel, the parts often end up warped. We tried clamping all the pieces down before welding. When we remove the clamps, the parts are warped. What can we do to prevent the parts being distorted after welding?

A: All welders have faced the problem of weld distortion at one time or another. The parts start off straight and square, and after welding, the finished part is warped. Thinner material is more susceptible, as it has less stiffness. Also stainless steels are more susceptible, as it has greater thermal expansion and lower thermal conductivity than carbon steels.

First, let's discuss why distortion occurs. Weld metal is deposited at a high temperature, above the melting point of material. For steel, this is around 2,500°F (1,370°C). As the weld cools to room temperature, it shrinks, but is restrained from doing so by the adjacent cold base metal, resulting in high-residual tensile stress. The weld is now like a stretched rubber band, with the workpiece holding the ends. This is the reason that the base metal moves, or springs back, when the clamps holding the workpiece are removed, distorting the part.

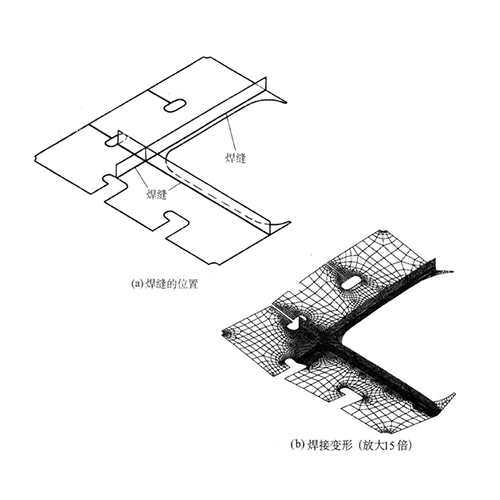

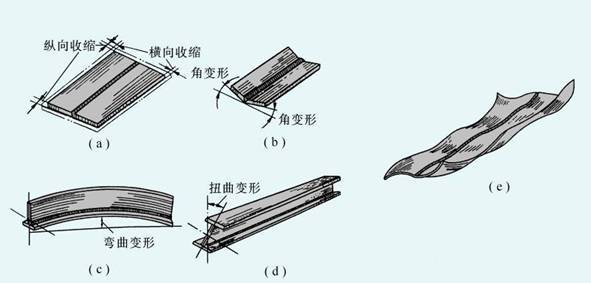

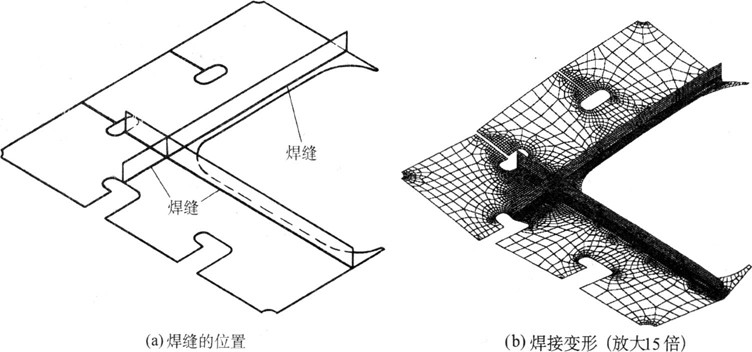

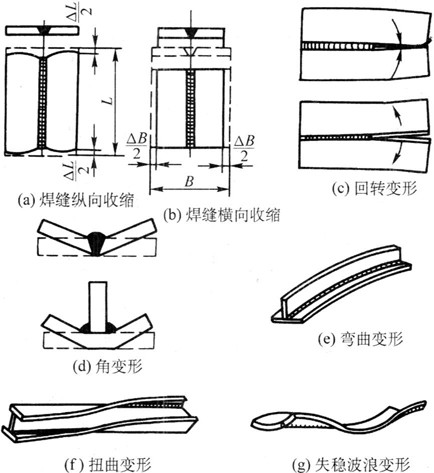

When the weld shrinks across its width, it causes groove welds to “wing-up” or fillet welds to close up. When the weld shrinks along its length, it causes base metal to twist around the weld.

To minimize weld distortion, design and welding should be addressed. Weld shrinkage cannot be prevented, but it can be controlled. These are recommended steps for minimizing weld distortion:

1.Avoid overwelding — The bigger the weld, the greater the shrinkage. Correctly sizing a weld not only minimizes distortion, but also saves weld metal and time.

2.Intermittent welding — To minimize the amount of weld metal, use intermittent welds instead of continuous welds where possible.

3.Fewer weld passes — A fewer number of big passes results in less distortion than a greater number of small passes with small electrodes. Shrinkage accumulates from each weld pass.

4.Place welds near the neutral axis, or the center of the part — Distortion is reduced by providing less leverage for the shrinkage forces to pull the plates out of alignment.

5.Balance welds around the neutral axis — Welding on both sides of the plate offsets one shrinkage force with another, to minimize distortion.

6.Use the backstep welding technique — In the backstep technique, the general progression of welding may be left to right, but each bead segment is deposited from right to left. As each bead segment is placed, the heated edges expand, which temporarily separates the plates at B. As the heat moves out across the plate to C, expansion along outer edges CD brings the plates back together. This separation is most pronounced as the first bead. With successive beads, the plates expand less and less because of the restraint from the prior welds.

7.Presetting the parts — Presetting parts before welding can make shrinkage work for you. The required amount of preset can be determined from a few trial welds.

8.Alternate the welding sequence — A well-planned welding sequence involves placing weld metal at different points of the assembly so that, as the structure shrinks in one place, it counteracts the shrinkage forces of welds already made. An example of this is welding alternately on both sides of the neutral axis in making a complete joint penetration groove weld in a butt joint.

9.Clamping — Clamps, jigs, and fixtures that lock parts into a desired position and hold them until welding is finished are probably the most widely used means for controlling distortion in small assemblies or components. While there is some movement or distortion after the welded part is removed from the jig or clamps, it will be lower compared to the amount of movement that would occur if no restraint were used during welding.

10.Peening — Peening the weld bead stretches it and relieves the residual stresses. However, peening must be used with care. For example, a root bead should never be peened, because of the increased risk of concealing or causing crack. Also, peening is not permitted on the final pass, because it can cover a crack and interfere with visual inspection. Before peening is used on a job, engineering approval should be obtained.

11.Thermal stress relieving — Another method for removing shrinkage forces is thermal stress relieving, i.e., controlled heating of the weldment to an elevated temperature, followed by controlled cooling.