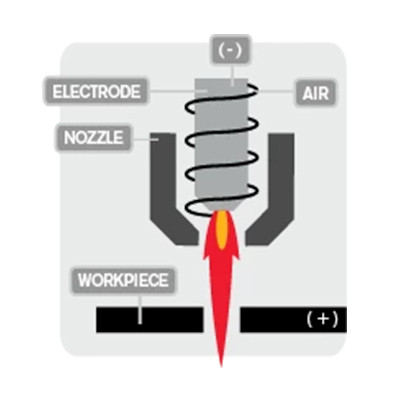

Conventional single flow plasma

- Share

- Issue Time

- Aug 18,2017

Conventional single flow plasma

This process generally uses a single gas (usually air or nitrogen) that both produces and cools the plasma.

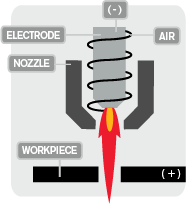

Dual flow plasma (unshielded)

This process utilizes two gases; one for the plasma and one as a shield gas. In smaller systems (under 125 amps), compressed air is often used as both the plasma and shield gases. Dual gas unshielded systems have an exposed nozzle and should not be used for drag cutting.

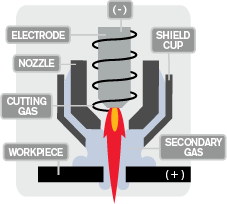

Dual flow plasma (shielded)

This process uses two gases, a plasma gas and a shield gas. In systems under 125 amps, air is often used as both plasma and shield. The advantage of the shield technology is that it electrically insulates the nozzle from contact with molten metal blowback from piercing, and also allows for drag cutting in hand applications. Further enhancements (conical flow technology) have improved cutting performance and nozzle life on some systems .

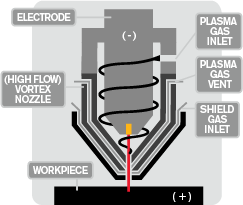

High definition class plasma

In this process, a specialized nozzle design narrows the arc and increases energy density. Because of the higher arc energy, high definition plasma achieves superior cut quality on materials up to 50 mm (2”) with superior cut edge angularity, narrower kerf and higher cut speeds than conventional plasma cutting technology. It's not uncommon with these systems to achieve cut part accuracies within the +/- 0.25 mm (0.010") range.

Today’s high definition systems allow very high levels of automation, and are intended for automated applications only. In the most advanced systems, virtually all of the machine operator’s expertise (required to get good cut quality on earlier plasma systems) is essentially captured in the CAM software that manages the day-to-day cutting operations.

With high definition plasma, cut holes are round and have virtually no taper. Edges are square and dross free. Cut-to-cut cycle times allow much higher levels of productivity. A single-plasma system can cut material thicknesses from thin gauge to over 182 mm (6”), using the same torch. The torch can cut and mark the plate through he same nozzle orifice.