Hints & Tips

- Share

- Issue Time

- Aug 24,2017

Hints & Tips

How do I TIG weld?

"How-To Weld" Summary

1. Establish an arc.

2. Create a weld puddle.

3. Add filler metal "dip" into the puddle while pushing the weld puddle along the weld joint.

4 .End the arc and leave the torch over the weld puddle to protect it until the puddle cools.

How do I prepare my weld joint?

Cleaning both the weld joint area and the filler metal is an important preparation. Remove all oil, grease, dirt, paint, etc. The presence of these contaminants may result in arc instability or contaminated welds.

Clamping may be required if the work piece cannot be supported during welding.

Make short 1/4 in. tack welds along the work pieces to hold them together.

How do I position my TIG torch for different types of joints?

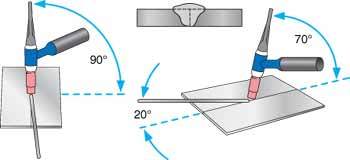

Butt welds

When welding a butt joint, center the weld pool on the adjoining edges. When finishing, decrease the heat (amperage) to aid in filling the crater.

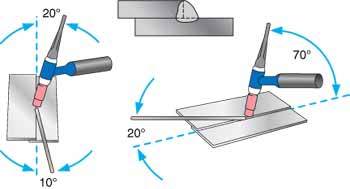

Lap joint

For a lap weld, form the weld pool so that the edge of the overlapping piece and the flat surface of the second piece flow together. Since the edge will melt faster, dip the filler rod next to the edge and make sure you are using enough filler metal to complete the joint.

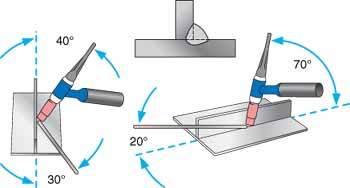

T-joint

When welding a T-joint, the edge and the flat surface are to be joined together, and the edge will melt faster. Angle the torch to direct more heat to the flat surface and extend the electrode beyond the cup to hold a shorter arc. Deposit the filler rod where the edge is melting..

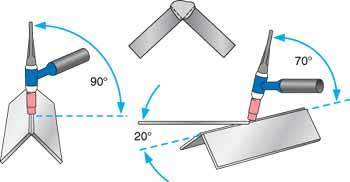

Corner joint

For a corner joint, both edges of the adjoining pieces should be melted and the weld pool should be kept on the joint centerline. A convex bead is necessary for this joint, so a sufficient amount of filler metal is neede

What can I do to improve arc starting?

Use the smallest diameter tungsten possible for the amperage you are using. Match the tungsten electrode size with the collet size.

Purchase the highest quality tungsten available - ask your distributor for Miller-branded tungsten. Use a premium quality torch and work leads.

Keep the torch and work leads as short as possible and move the power source as close as possible to the work

Make sure the Stick electrode holder is detached from the machine before TIG welding.

Check and tighten all connections.

Keep the torch cable from contacting any grounded metal.

Use 100% argon shielding gas.

When welding aluminum, use AC current and a ceriated (gray identifying band) or 1.5% lanthanated (gold identifying band) tungsten.

When welding steel and stainless steel, use DC-Straight Polarity (DCEN) and a 2% thoriated (red identifying band) tungsten . Prepare a pointed-end.

Always use a push technique with the TIG torch.

When welding a fillet, the leg of the weld should be equal to the thickness of the parts welded.