AC/DC How to Weld with Stick and TIG on Alternating Current

- Share

- Issue Time

- Nov 15,2019

Summary

AC versus DC is a long held debate. Is it better for a current flow to be unidirectional or alternating from positive to negative? In the end, DC is best for MIG welding and AC is best for TIG welding. AC is also suitable for stick welding. You will have to take some precautions. In any case, electricity is like fire and money; a wonderful servant but a terrible master. Use it wisely and you can be proud of a job well done.

AC vs DC Welding

When it comes to welding, most high-powered machines are run on DC or have the ability to change from DC to AC current like some professional TIG welders. Most of all metals and metal alloys except aluminum and magnesium are welded with DC, especially when wedding higher strength and low alloy steels. Direct current is the only way to do it.

Alternating current has its own uses with MMA (stick) and TIG welding processes. MIG welding to my knowledge can’t run on AC except some inexpensive ones called “buzz boxes”. There is no decent MIG welding machine out there that can perform well on AC. Some glassless flux core welders can give you a decent beat but then again it will be low penetration and with a lot of splatter.

In the MMA case, using special electrodes alternating current can help when base metal is magnetized and the “arc blow “appears. Switching to AC most often ends the problem.

In a TIG’s case, aluminum is always welded with AC current because of a special property of aluminum alloy that has a problem with melting point. This is a problem that Alternating current solves.

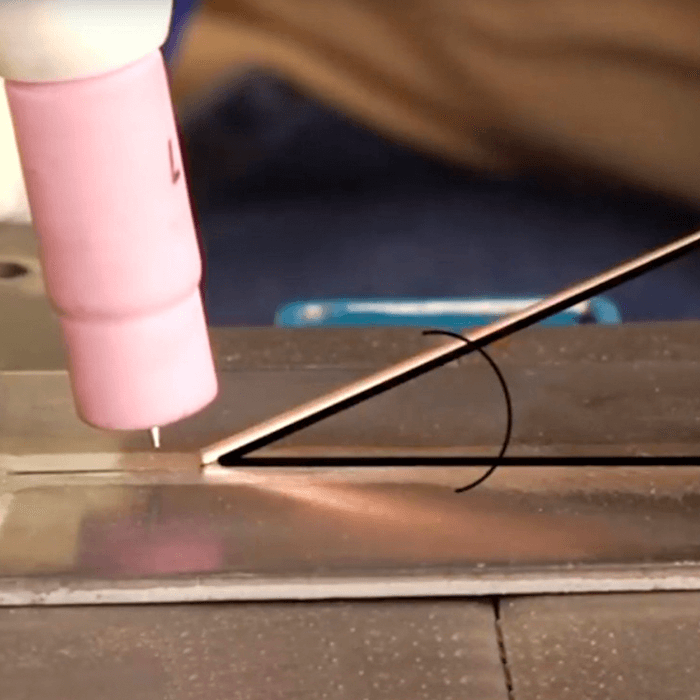

TIG welding on AC

As said above the only way to weld aluminum and magnesium with TIG process is on the alternating current. This is because aluminum has basically two layers, the base aluminum and aluminum oxide. The oxide is essentially formed when metal is exposed to air and it has much higher melting point of about 3600-degree F. For example, base aluminum melts at 1200-degree F.

The aluminum oxide must be cleaned off before the base metal starts to melt. If this is not performed the base metal can’t fuse properly. On thin sheets, base metal will overheat and liquefy before arc can get through the oxide.

Now that’s where AC’s clean properties come in. Alternate current can basically transform the torch into a ray-gun.

Now you know that the current flow moves from positive to negative and back again many times a second. So, when flow flips to electrode positive portion of the AC cycle (when current flows from base metal back to electrode) it actually provides a “cleaning” action and the electric arc blasts of surface oxides.

Then when the cycle alternates back into the electrode negative (current flows form electrode to base metal) and properly melts and fuses the aluminum base metal.

It is the best way to weld aluminum. It is low on speed but the quality of joint metal is superb and is aesthetically pleasing.

Stick (MMA) welding on AC

Note again that most of the welding is done on DC output, DC negative (-) called “straight” and DC positive (+) “reverse”. Of which DC+ is much more used today.

It produces a good bead profile, deep penetration and overall better weld properties (bending, durability, porosity etc.) for bridges, ships, building’s metal construction. Then pipes and root passes on pipes. Generally, welding on higher strength and low alloy steels are exclusively done with DC reverse.

DC- was once the norm for stick welding before the invention of inverter technology. Now it is used on thin sheet metal in an attempt to prevent burning through the material or on places where metal would not be exposed to extreme temperature changes or hazardous water.

So why then use AC at all? Well, often there comes the problem in stick welding. It’s a huge problem and no matter how good of a welder you are or how well you prepare and clean base metal you will not be able to weld it successfully. This phenomenon is called the “arc blow”.

Sometimes you will be able to solve it by changing the electrode or moving a ground clamp to another place. However, if that doesn’t work, the only solution is the alternate current. It occurs because the base metal is too magnetized or there is a current problem whatever it is, the arc from the electrode starts to slide to one side or the other.

It starts to spit metal drops on one side and burn/melt the material on the other. AC current’s fast altering nature successfully eliminates this problem.

Conclusion:

AC versus DC is a long held debate. Is it better for a current flow to be unidirectional or alternating from positive to negative? In the end, DC is best for MIG welding and AC is best for TIG welding. AC is also suitable for stick welding. You will have to take some precautions. In any case, electricity is like fire and money; a wonderful servant but a terrible master. Use it wisely and you can be proud of a job well done.