WHEN DO I USE TIG WELDING?

- Share

- Issue Time

- Dec 6,2019

Summary

Your use of MIG or TIG welding could be the difference in your project that takes it to the next level. You could greatly reduce the time and effort spent making it and improve the quality and durability of the final product.

TIG WELDING APPLICATIONS:

1. If your project uses thinner metal or is smaller, then TIG is the way to go. It’s better for precise welds that leave your project looking great and requires little to no cleaning.

2. TIG welding is a three-part process where you need to have strong hand-eye and hand-foot coordination. It’s a delicate technique that needs practice and patience. The foot control allows for more precision when controlling the heat.

3. While welders like using the foot pedal for TIG welding, that method might not work when you’re trying to weld smaller areas at odd angles. For these, consider using finger-tip control so you can get to those angles and weld them correctly.

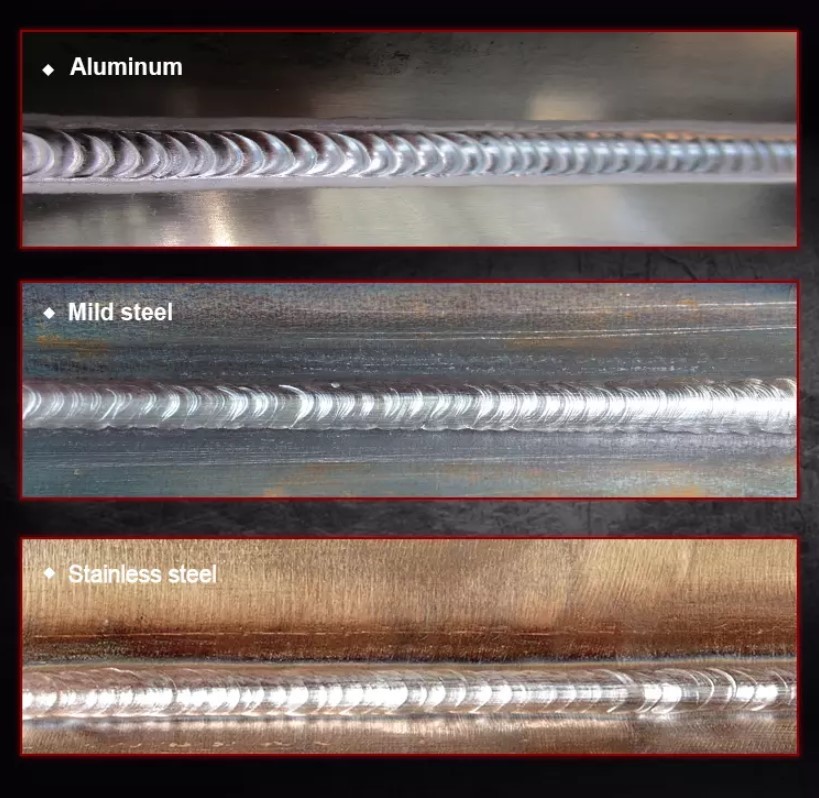

4. TIG can work with many kinds of metal, like aluminum and copper, but not with cast iron.

5. Short-run, technical welds are best for TIG welding. Longer runs can be more difficult and expensive.

6. If your project is something like a toolbox or a sink, TIG is a better option. TIG also works best with artwork, such as ornamental designs and automotive projects.