WHY MIG WELDING IS BETTER THAN TIG WELDING?

- Share

- Issue Time

- Dec 11,2019

Summary

Arc welding processes are as varied as the work pieces they create, and choosing the right one is vital to your project’s success. While MIG and TIG welding both form the weld using an electric arc, the techniques are quite different, and choosing the wrong one can lead to more than one headache. Read on for the reasons you may want to choose MIG welding vs. TIG welding.

Arc welding processes are as varied as the work pieces they create, and choosing the right one is vital to your project’s success. While MIG and TIG welding both form the weld using an electric arc, the techniques are quite different, and choosing the wrong one can lead to more than one headache. Read on for the reasons you may want to choose MIG welding vs. TIG welding.

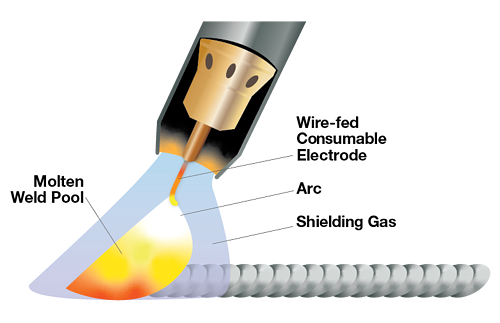

MIG and TIG welding both use an electric arc to create the weld. The difference between the two is the way the arc is used. MIG (metal inert gas) welding uses a feed wire that constantly moves through the gun to create the spark, then melts to form the weld. TIG (tungsten inert gas) welding uses long rods to fuse two metals directly together.

1.DIVERSITY

A number of reasons make MIG welding the superior choice for your job. First, it’s more diverse. While TIG welding can be used on more types of metals, it’s limited in its effectiveness on thicker jobs. MIG welding can be used on aluminum, stainless steel and steel, and on every thickness from 26-gauge sheet metal to heavy-duty structural plates.

MIG welding holds this big advantage over TIG because the wire feed acts not only as an electrode, but also as filler. As a result, thicker pieces can be fused together without having to heat them all the way through. And because it uses filler rather than fusing, MIG welding can be used to weld two different materials together.

2.SPEED

Another reason for choosing MIG vs. TIG is speed. A MIG gun is designed to run continuously for long periods of time, making them more efficient and productive than its counterpart. For large, industrial operations that require high production rates, MIG is the go-to choice. (It also lends itself well to automation). Oppositely, TIG welding is much slower process that’s focused on detail.

3.COST

As with any manufacturing job, time equals money. And because the MIG welding process is so much faster, it’s also more cost-effective. MIG parts are also more readily available and far less expensive than TIG.

4.EASE

Finally, MIG welding is easier to learn and can be perfected after just a few weeks of training. In fact, it’s even been referred to as the “hot glue gun” of welding -- just pull the trigger to start or stop the weld. MIG welders can hold and operate the gun with only one hand, making it a better option for beginning welders. TIG welding, on the other hand, is a specialized technique that requires the use of both hands and one foot -- all doing separate things.