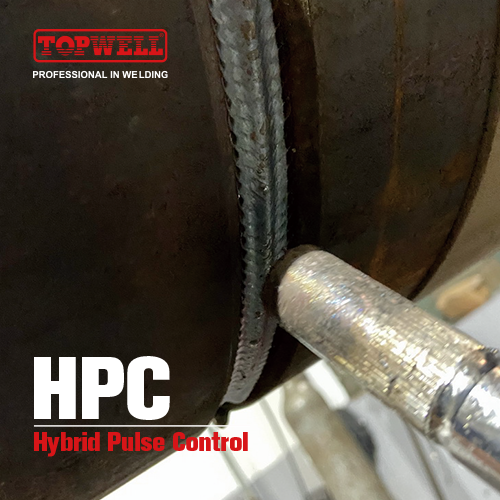

HPC—Hybrid Pulse Control Optismised for all position welding

- Share

- Issue Time

- Sep 30,2022

Summary

Optismised for all position welding | 100% faster vertical welding | Deep penetration

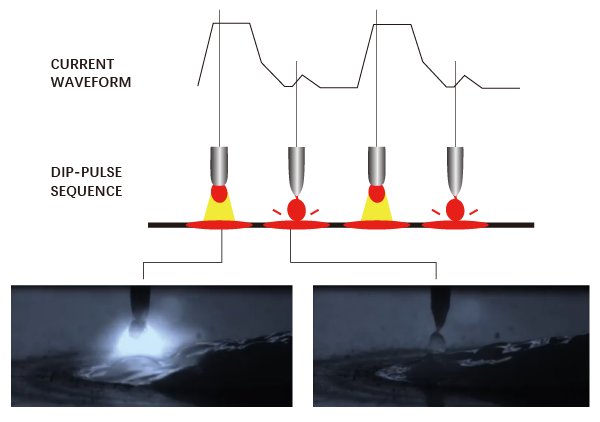

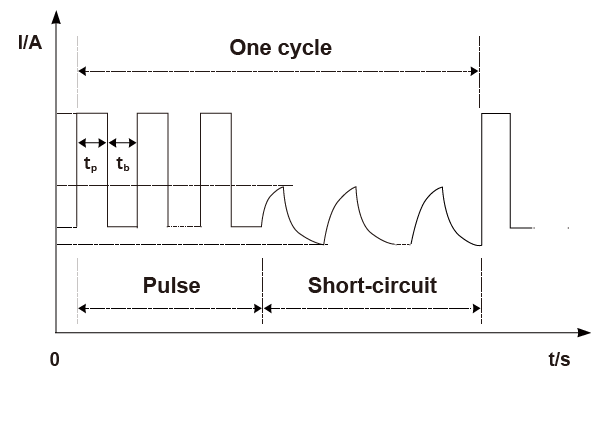

THE HYBRID PULSE CONTROLS PROCESS

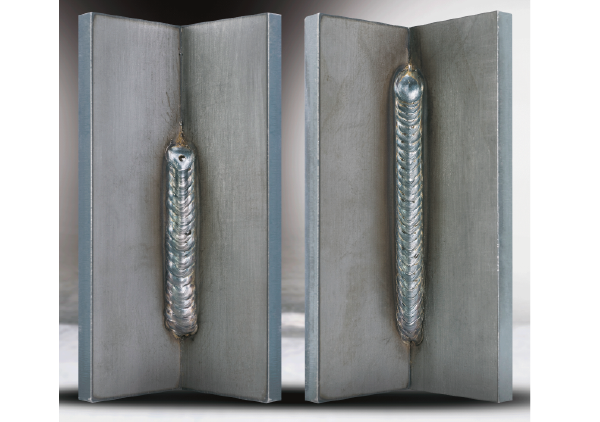

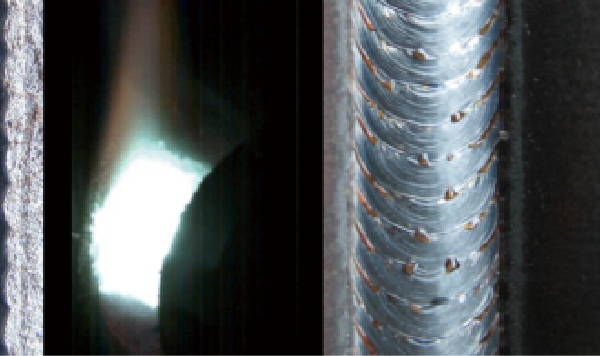

HPC——Hybrid Pulse Control process is synergetic waveform controlled welding process control variants applied in MIG welding. which are Pulse (spray arc) and short-circuit transfer types in one duty cycle. It adopts the smooth switching technology of short-circuit and pulse. By alternately outputting pulse and short-circuit current, the molten pool is heated and cooled periodically, forming fish scale pattern. Thus HPC is particularly suitable for all poisition welding, especially vertical up welding.

THE ADVANTAGES

Optismised For All Position Welding

Precious heat input and synergetic hybrid waveform controlled process ensured the high productivity during all position welding,especially vertical welding.

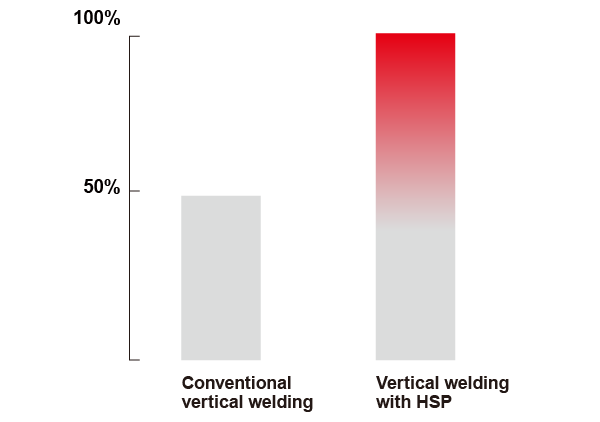

Faster Welding Spped

- Vertical up welding without waving

- simplified user operation

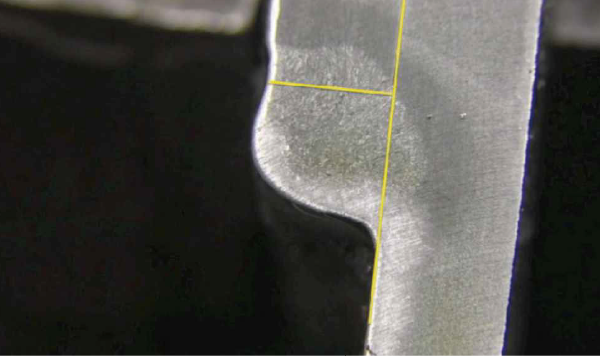

Higher Welding Strength

- Reliable root coverage

- Deep penetration

- Superior throat thickness and edge wetting

Better Welding Seam

- Fast with minimum spatter

- no undercut defect

- even, slightly rippled weld surface

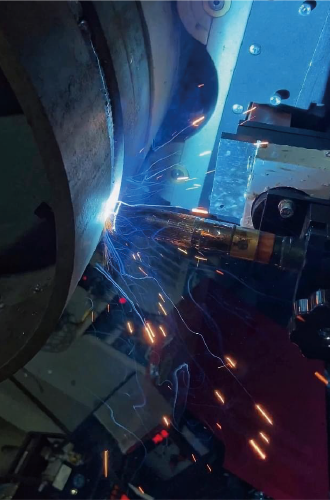

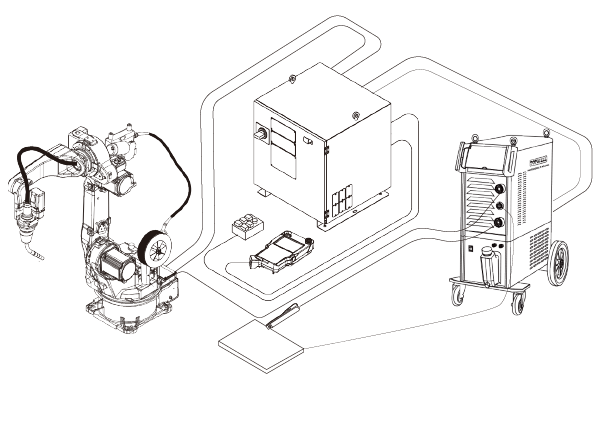

Automation Welding

Continuous movement in the mechanised torch guidance is very good for automation/very simple manual torch guidance.

THE APPLICATIONS OF HPC

Designed for welding with robot