Soldadora pulse mig 250amp welding equipment PROMIG-250SYN DPulse

- Model

- PROMIG-250SYN DPulse

Item specifics

- Rated Input Voltage

- 1PH~230V ±15%/3PH~400V ±15%

- MAX.Load Power Capacity

- 11.72KVA

- Rated Output

- 250A/26.5V

- Open Circuit Voltage

- 70V-80V

- Effiency

- 80%

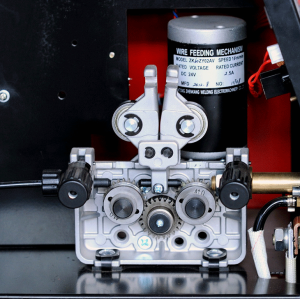

- Wire-feed Mechanism

- 4Rollers

- Wire Feed Speed Range

- 2-25m/min

- Warranty

- 3 year warranty

- Dimension

- 790x250x650mm

- Weight

- 32KG

Review

Description

-

PROMIG-250SYN DPulse

TOPWELL double pulse mig mag welder for aluminum welding Promig-250syn pulse

-

Application:

Metal Fabrication

Maintenance and Repair

Auto Body

Light Industrial,Workshop -

Processes:

Pulse Process For M.S/AL

Double Pulse Process For M.S/AL

MIG/MAG

Flux-Cored

MMA(Stick) -

Input Power:

1PH ~ 230V ±15%/3PH ~ 400V ±15%

Amperage Range: 10-250A

Rated Output at 40℃ (104℉):

250A /26.5V/60% Duty Cycle

Weight: 32KG

Advanced Features

· Multi-Process Capable - Multi-Process Capable - Welds flux-cored, stick, TIG, pulsed MIG, and advanced processes like Double Pulse MIG*.

· Pulse MIG Process - Welds Mild steel, 4XXX and 5XXX series aluminum for superior quality welding.

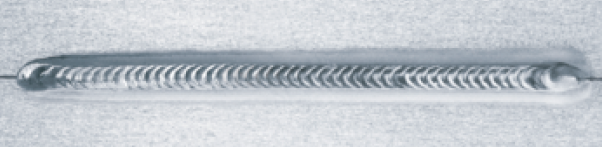

· Double Pulse MIG Process - Delivers a staked dime appearance when welding mild steel and aluminum.

· Synergic Control -Set weld procedures with one control.

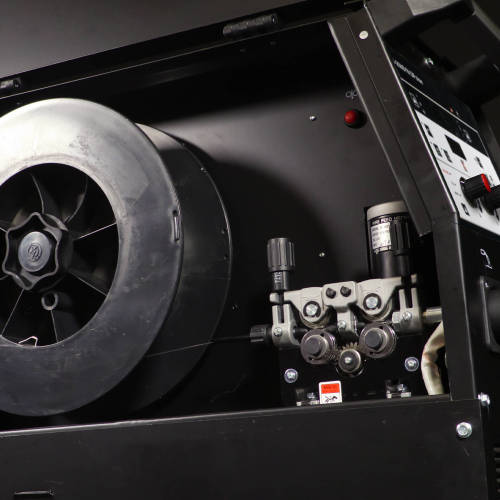

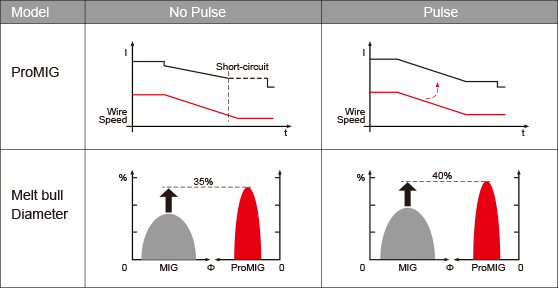

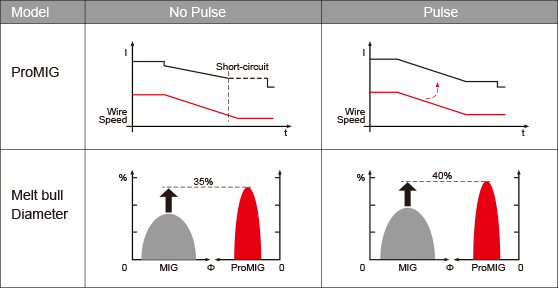

· Professional 4-Rollers Drive System - Allows for constant wire feed speed and consistent welds.Pulse MIG

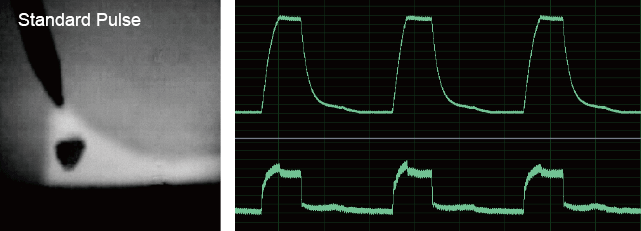

· The Pulse MIG process works by forming one droplet of molten metal at the end of the electrode per pulse. Then, just the right amount of current is added to push that one droplet across the arc and into the puddle. The transfer of these droplets occurs through the arc, one droplet per pulse.

· It minimizes warping and burnthrough on thin materials, not only for Aluminum, but also for Mild Steel. Moreover, it delivers ultra low spatters which is outstanding for Mild Steel welding.

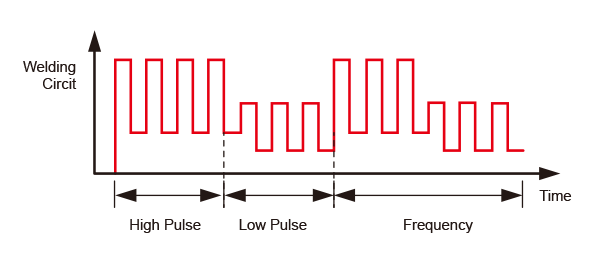

DOUBLE PULSE

Compared with the traditional DoublePulse, High Speed Double Pulse process can increase the welding speed by about 25%. Welding quality is comparable to TIG process.

No need to swing, You can easily get a cosmetically pleasing weld seam, with significantly lower and more controller heat input into the workpiece. It results in much lower distortion and less rework, very suitable for welding the thin Aluminum or S.S sheets.

By High-Speed Double Pulse process, the heat input of arc is alternating, effectively reducing the heat input of base metal. It reduces the occurrence of welding defects such as crack.

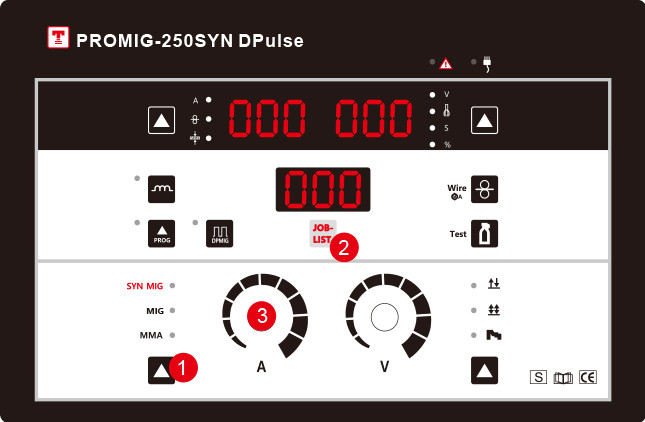

SIMPLE OPERATION

3 Steps to achieve weld perfection

1. Select operation mode

2. Select Job-list No.

3. Adjust welding current

(always the perfect setting by the synergic function

using the material thickness)

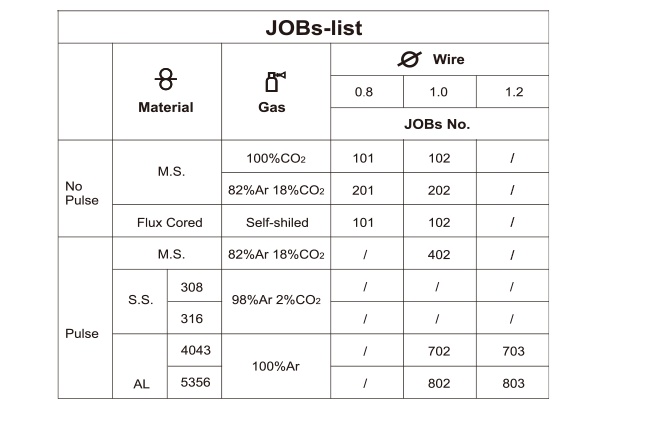

Synergy control with job-list

The Job-lists display is easily and intuitively controlled through its graphical user interface.We assembled the perfect welding curve in every Job-No. for highly efficient multi-process welding of carbon steels and stainless steel and aluminum alloys. Operation is easier than ever before.

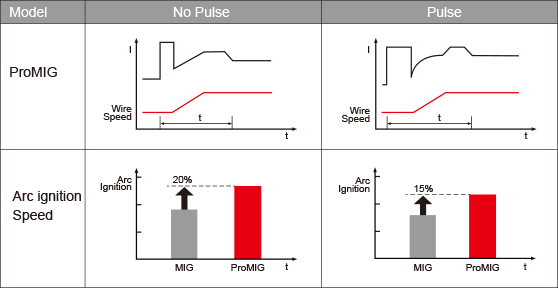

IMPROVED OPERATION PROCESS & CONTROLS

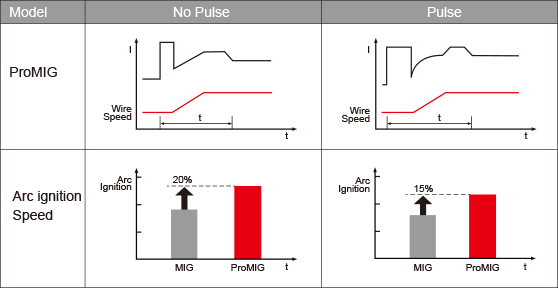

Initial Arc control

We control the arc energy by welding waveform, so the success rate of arc ignition can be improved and quickly establish a molten pool.

Burn Back control

Adjustable time delay between turning off the arc and the wire feed to prevent wire sticking to the puddle.

Burn Back control

Adjustable time delay between turning off the arc and the wire feed to prevent wire sticking to the puddle.

Initial Arc control

We control the arc energy by welding waveform, so the success rate of arc ignition can be improved and quickly establish a molten pool.

-

-

Item No PROMIG-250SYN DPulse Rated Input Voltage 3PH ~ 400V ±15% Max. Load Power Capacity 11.72KVA Rated Duty Cycle(40℃) 60% MIG: 250A/26.5V MMA: 250A/30V TIG: 250A/20V 100% MIG: 200A/24V MMA: MMA: 200A/28V TIG: TIG: 200A/18V Welding Current/Voltage Range MIG: 10A/14.5V~300A/29V MMA:10A/20.8V~250A/30V TIG:5A/10.2V~250A/20V Open Circuit Voltage 70V~80V Power Factor 0.8 Efficiency 80% Pre-Gas Time Preset Flow-Gas Time Preset Wire-feed Mechanism 4 Rollers Wire-feed Speed Range 0~25 m/min Wire Spool Capacity 300mm (15kg) Filler Wires (mm) for Fe : 0.8~1.2 mm For Stainless steel: 0.8~1.2mm For Aluminum: 0.8~1.2mm Dimension 790X250X650mm Weight 32KG - For Standard accessories

MIG torch:MIG-24

Electrode holder with cable 2M

Earth clamp with cable 2MFor Optional accessories

BINZEL MB EVO PRO 24

Argon gas regular

or co 2 gas regular with heater

Push-pull Troch:

QTLB-24KD/36KD

TIG Troch:TIG-26

-

-

Q:Are you a factory or a trading company?

A: We are factory with more than 10 years manufacturing experience and we provide perfect OEM and after-sale service.

Q:How can I pay my order?

A: We accept T/T, Western Union, Alibaba Trade Assurance payments. For those orders less than 1000USD, we accept PayPal to pay.

Q:How about your warranty?

A: We offer 3-year product life guarantee ,and a generous 1 year warranty on al purchases that begins with the bill of lading.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Q:How can I get the quotation?

A: We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price,please send the message on trade management or call us directly