Stainless Steel DC TIG welding machine PROTIG-500CT water cooling unit

- Model

- PROTIG-500CT

Item specifics

- Input Voltage

- 3PH ~ 400V ±15%

- Rated Output(40℃) 60%

- TIG: 500A/30V

- Output Range

- 20A/10.8V~500A/30V

Review

Description

DETAILS

Powerful output, Heavy duty for industrial,

Outstanding performance

PROTIG-500CT

Powerful output - 500A @ 60% Duty cycle.

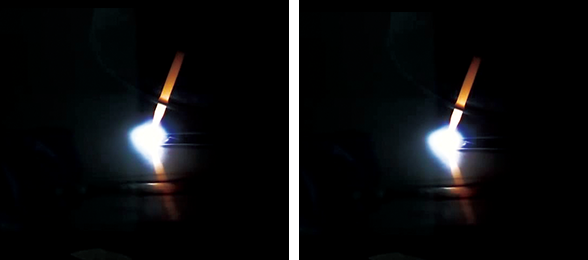

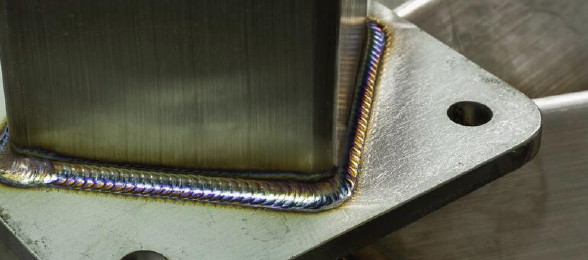

Advanced Pulse control - Minimize heat input on thin materials, and provide for a faster freezing weld puddle for uphill welding on curved surfaces such as process piping. The TIG pulse also helps moderate filler metal deposition for consistent bead appearance.

High-Frequency start - Makes it easy to establish an arc under a variety of conditions.

Hot Start & Arc Force – Makes it easy to start and powerful arc in MMA welding.

Advanced Pulse TIG

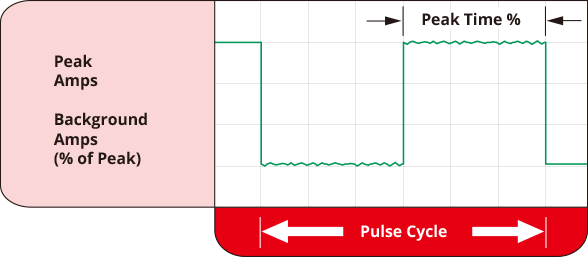

Conventional Pulse TIG

Typically from 0.2 to 10 PPS. Provides a heating and cooling effect on the weld puddle and can reduce distortion by lowering the average amperage. This heating and cooling effect also produces a distinct ripple pattern in the weld bead. The relationship between pulse frequency and travel speed determines the distance between the ripples. Slow pulsing can also be coordinated with filler metal addition and can increase overall control of the weld puddle.

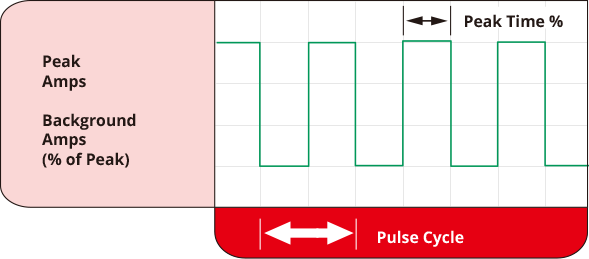

High Frequency Pulse TIG

In excess of 40 PPS, Pulsed TIG becomes more audible than visible causing increased puddle agitation for a better as-welded microstructure. Pulsing the weld current at high speeds between a high Peak and a low Background amperage can also constrict and focus the arc. This results in maximum arc stability, increased penetration and increased travel speeds.

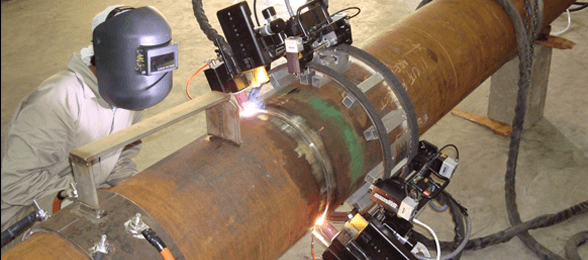

Pressure Pipelines Application

ProTIG-500CT + Cold Wire Feeder + Carriage

This system is a solution for pressure pipelines. It is 500A @ 60% Duty Cycle. With the precise arc control, it delivers deep penetration and high-quality welding seams.

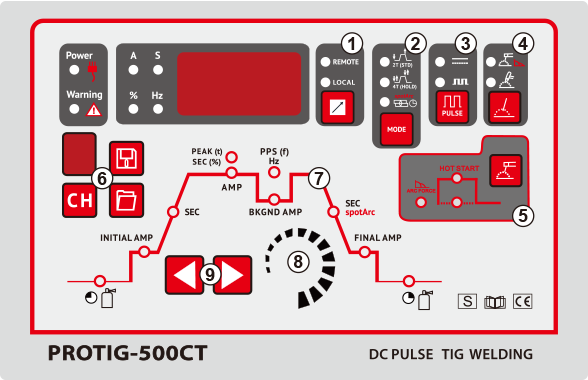

General View of Control Panel

1. Remote: used for foot pedal or Remote torch.

Local: adjusted Currents by face panel

2. 2T/4T holding mode or Spot Welding mode selection

3. Pulse ON/OFF selection.

4. Process selection

5. ARC FORCE/HOT START

6. Memory with capacity of 10 sets parameters

7. Function Sequence

8. Encoder Control

9. Select welding parameters button

SPECIFICATIONS

Machines

|

Product Name

|

ProTIG-500CT

|

|

Machines Processes

|

Stick (SMAW) TIG (GTAW) Pulsed TIG (GTAW-P) |

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

960x420x900mm

|

|

Net Weight

|

70KG

|

Basic Specification

|

Input Voltage

|

3PH ~ 400V ±15%

|

|

Input Power

|

TIG: 20.76 KVA MMA: 19.93 KVA |

|

Output Range

|

TIG: 20A/10.8V~500A/30V MMA: 20A/20.8V~400A/36V |

|

Rated Output(40℃) 60%

|

TIG: 500A/30V MMA: 400A/36V |

Polarity | DC |

YOU MAY ALSO NEED