Heavy Duty AC/DC TIG welder for heavy industrial and professional welding with IGBT module TOPWELL MASTER TIG-500CT

- Model

- MASTERTIG-500CT

Item specifics

- Input Voltage

- 3PH ~ 400V ±15%

- Rated Output(40℃) 60%

- 500A/30V

- Features

- AC TIG, MIX TIG, DC TIG

Review

Description

DETAILS

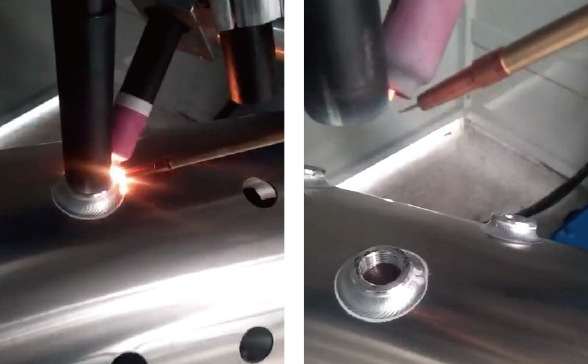

Total Solution of TIG welding

AC/DC TIG & MIX TIG

MASTERTIG-500CT

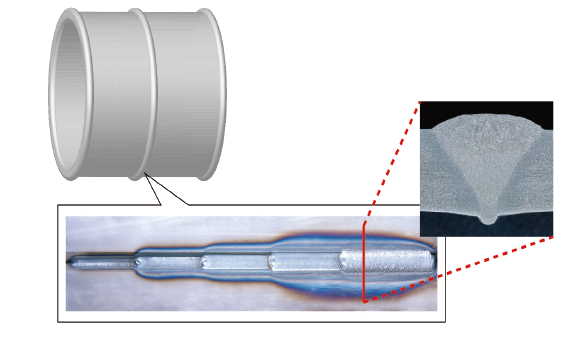

DC TIG - features the Pulse function, it precisely controls the welding arc, heat input and penetratoin.

AC TIG - with 2 kinds of AC waveshapes(square wave and sin wave), and 3 kinds of AC waveshape controls(Balance, Frequency and Amplitude).

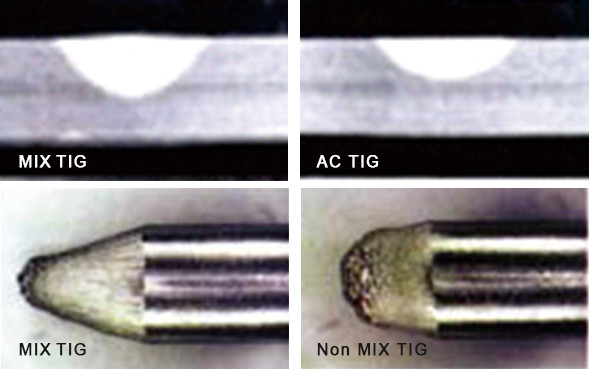

MIX TIG- has both AC current and DC current in one duty cycle, better arc concentration and deeper penetration.

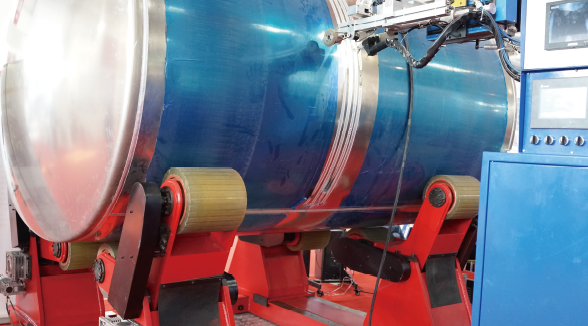

Reliable and Powerful Design - 500A@100% duty cycle, capable for Light Industrial jobs.

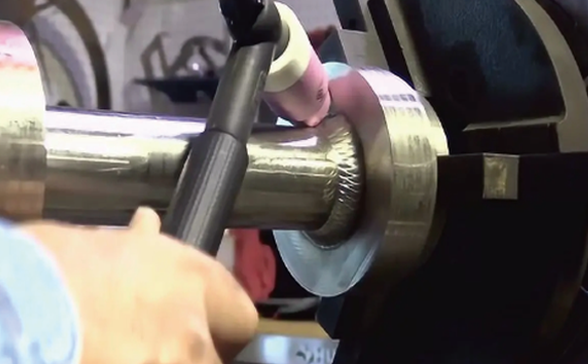

High Efficiency TIG Welding

This is a three-phase TIG welder equipped with the latest IGBT modules. It also features an integrated cooling unit that provides efficient cooling for liquid-cooled torches in high-load production welding environments. The shape of the arc, weld penetration, cleaning effects and other characteristics are precisely controlled to ensure that the weld quality is always high.

High Efficiency TIG Welding

Maximum output is up to 500A. It is capable of fast welding of thin metals and continuous welding of thick metals.

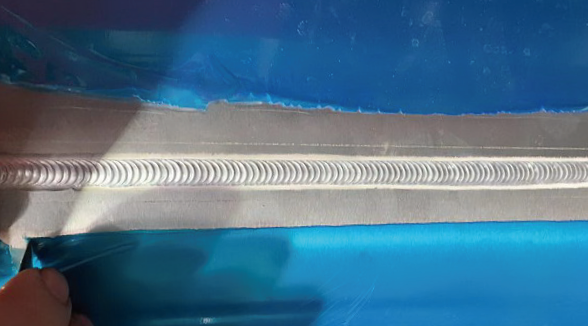

Mild steel 12mm V groove, 5 layers;

Layer 1: 300A, Layer 2: 300A,Layer 3: 280A;

Layer 4: 280A, Layer 5: 260A;

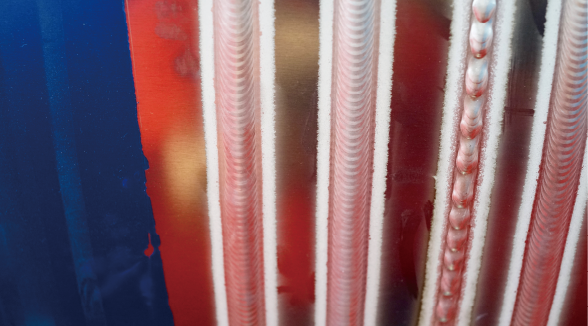

Unique MIX TIG

· Deeper penetration

· Substantially reduce the tungsten consumption

Control Panel Description

1. Welding Process

DC TIG/AC TIG/MIX TIG/DC MMA

2. Pulser Control

3. AC Waveshape Types

Advanced Squarewave

Sin Wave

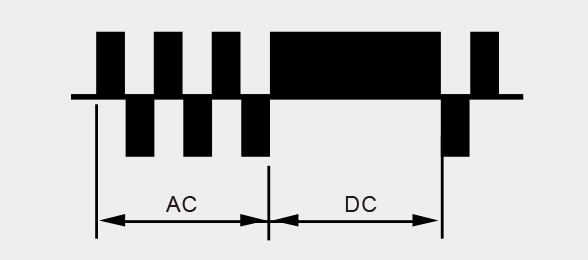

4. MIX TIG

5. AC Waveshape

AC Frequency Range 20Hz~200Hz

AC Clean Width (AC Balance) +40~-40

AC Clean Ratio (ACBias) % +30~-50

AC Frequency control

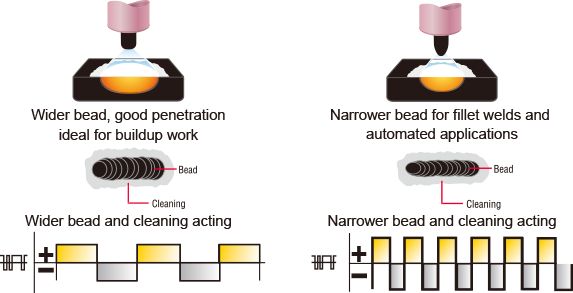

Controls the width of the arc cone. Increasing the AC Frequency provides a more focused arc with increased directional control.

Note: Decreasing the AC Frequency softens the arc and broadens the weld puddle for a wider weld bead.

AC Balance Control

Controls arc cleaning action. Adjusting the % EN of the AC wave controls the width of the etching zone surrounding the weld.

Note: Set the AC Balance control for adequate arc cleaning action at the sides and in front of the weld puddle. AC Balance should be fine tuned according to how heavy or thick the oxides are.

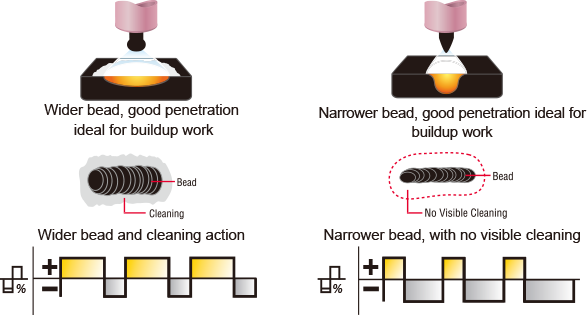

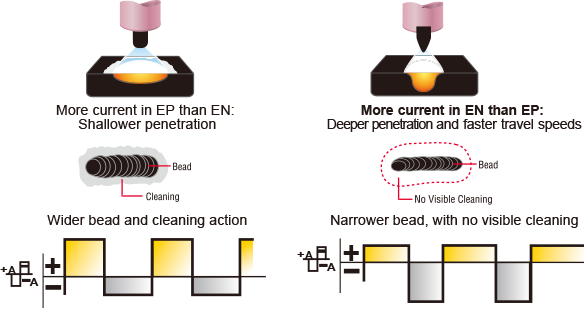

Amplitude Control

Adjusts the ratio of EN to EP amperage to precisely control heat input to the work and the electrode.

Note: EN amperage controls the level of penetration, while EP amperage dramatically effects the arc cleaning action along with the AC Balance control.

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

MasterTIG-500CT

|

|

Machines Processes

|

Stick (SMAW)

TIG (GMAW) Pulsed TIG (GTAW-P) |

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

960x420x900mm

|

|

Net Weight

|

80KG

|

Basic Specification

|

Input Voltage

|

3PH ~ 400V ±15%

|

|

Input Power

|

TIG: 20.76KVA MMA: 19.93KVA |

|

Output Range

|

TIG: 20A/10.8V~500A/30V MMA: 20A/20.8V~400A/36V |

|

Rated Output(40℃) 100%

|

TIG: 500A/30V MMA: 400A/36V |

Polarity | AC/DC |

YOU MAY ALSO NEED