STEELMATE PRO 500 comprised of a variety of advanced welding processes heavy duty mig welders

- Model

- STEELMATE PRO 500

Item specifics

- Mains voltage(V)

- 3PH~400V±15%(50/60Hz)

- Max.Load Power Capacity

- 25.18KVA

- Output Range

- 30A/15.5V~500A/39V

- Rated Duty cycle at 40℃(105℉): 60%

- 500A/39V

Review

Description

DETAILS

STEELMATE PRO SERIES

Workhorse - Ideal for Heavy-duty Steel Welding

Quick Specs

|

Steelmate po Series

|

350 |

500 | 650 |

|

Input Voltage

|

3PH ~ 400V ±15% |

3PH ~ 400V ±15% | 3PH ~ 400V ±15% |

|

Rated Output(40℃) 60% |

500A/39V |

500A/39V | 650A/44V |

Cooling system | Air-cooled

| Air-cooled

| Air-cooled

|

Equipment

|

Welding process package

|

|

|

Short Arc (refined dip transfer)

|

•

|

Pulse Arc

| • |

HSP (high speed pulse) | • |

HSA (high speed spray arc)

| • |

UCA (ultra concentrated Arc)

|

○

|

HPC (hybrid pulse control)

| ○ |

Operational Method | |

At the remote control

| • |

At the wire feeder

| • |

At the remote control unit

| ○ |

At the torch

| ○ |

• Standard ○Optional

High Performance for Steel Welding

Equipped with refined dip transfer as well as high energy pulse and spray arc, the Steelmate PRO Series is able to provide solutions for all medium and thick sheet of steel welding. With superior function and performance but less cost, it is the most cost-effective choice for steel welding production use.

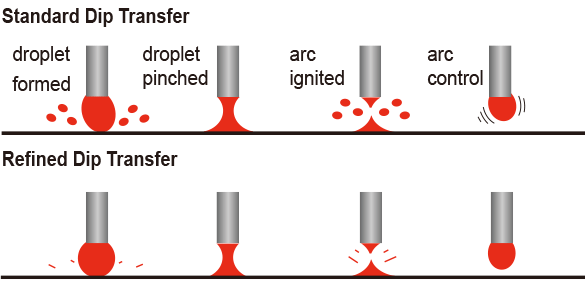

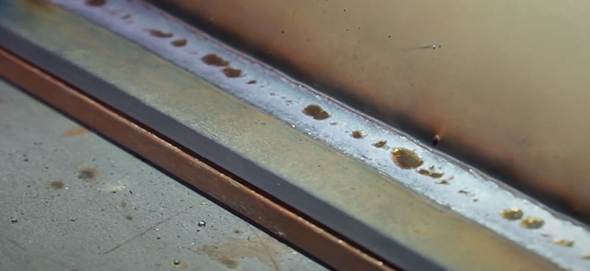

• Refined Dip Transfer

• Highly efficient dip transfer arc with refined waveform;

• Suppress the spatter during short-circuit transition;

• Create high-quality seams with increased deposition rate;

• Spatter can be reduced by 20% when welding with CO2;

• Improved Arc Length Controls

The extension self-adjusting function maintains the stability of the same short arc length, enabling constant and regular short circuits, despite the change in the welding torch position, changing sheet thicknesses, or material misalignment.

Benefiting from the wire feed control, the penetration stays stable and constant even in spite of the extension fluctuations.

• High-energy Arc for Steel Welding

Aside from refined dip transfer, the Steelmate Pro Series is equipped with two complimentary advanced MIG/MAG welding processes including HSP and HSA as a plus, which allows more complicated problems to be solved as well as better welding results to be delivered.

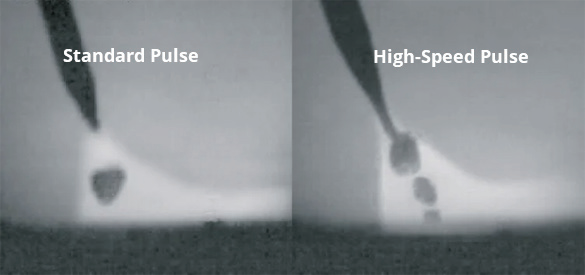

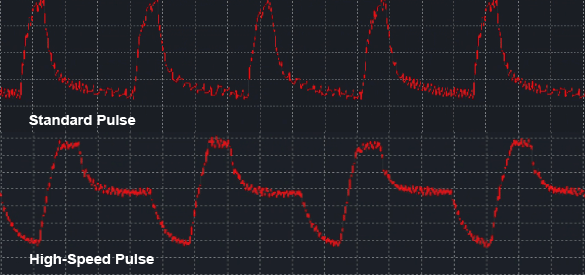

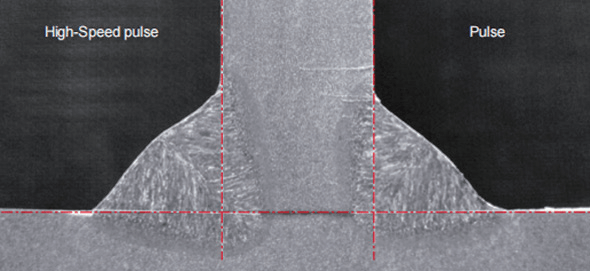

HSP (High Speed Pulse) - Ultra High Deposition Rate

Compared to a standard pulse process, the HSP extends its transition to a virtually flowing material transition to the work pieces, which boosts deposition rates by 35% while ensuring smooth, spatter-free seams. It users to save time, money, and resource as no reworks are required.

Get better welding seam

Less heat input, less spatters, less rework.

Get higher welding strength

Deeper penetration, no undercut defects, higher strength.

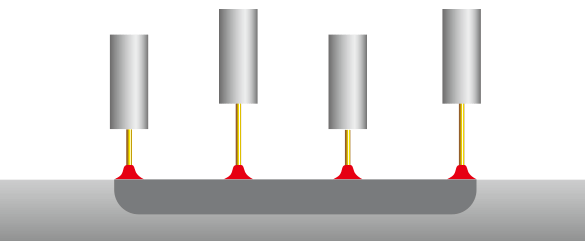

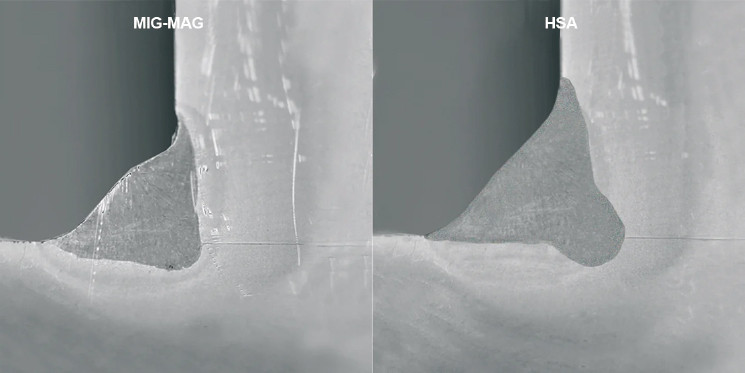

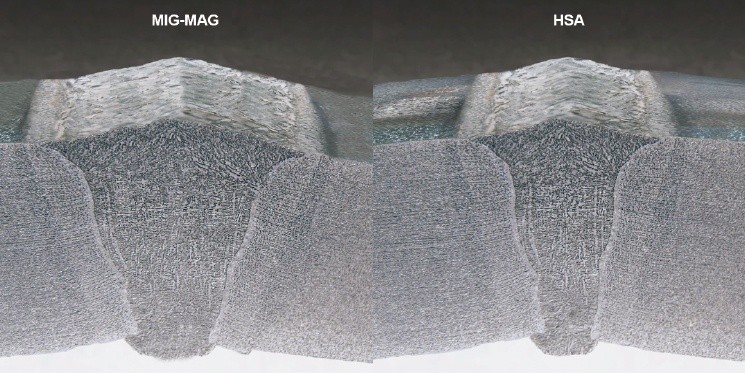

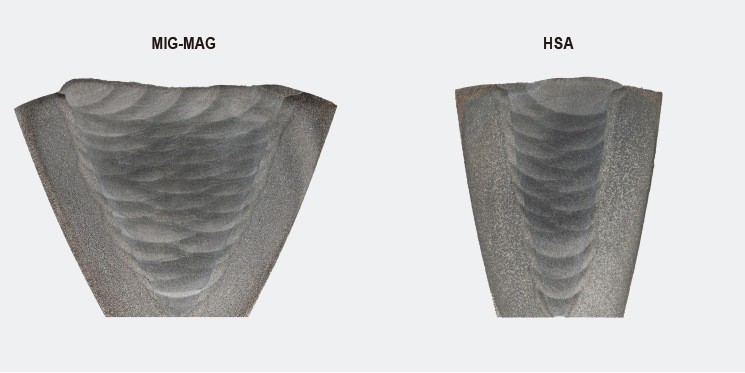

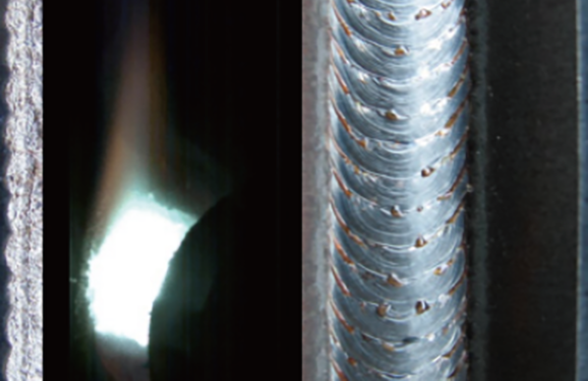

HSA (High Speed Spray Arc) - Superior Directional Property

With a highly concentrated and extremely stable arc in high density, the HSA process delivers spatter-free weld seems, deeper penetration and narrower heating affected zones. It is also possible to weld at small opening angles with the high directional property. Its welding speed is more than 30% faster than conventional MIG or MAG welding.

Smaller opening angle

Deeper penetration

More material saving

Higher welding efficiency

HPC (Hybrid Pulse Control) - Excellent in All-position Welding

The specialty of HPC-Vertical Up lies in two processes: one is to heat up the material with high energy, and another is to steeply lower the heat to contribute to the well-formation of seams within a short time.

It ensures a reliable penetration, precisely sized weld fillings, and a near-optimal throat thickness and is faster and easier than the conventional "X-Mas tree".

Also Good for Stainless Steel Welding

With the advanced welding processes equipped, the Steelmate PRO Series is not only a great mate for mild steel welding, but also good for stainless steel welding.

The Steelmate Pro single/double pulse technology optimizes welding results by precisely controlling heat input while maintaining metal fluidity, minimizing total heat input as much as possible to ensure excellent welding quality and preserve the original properties and mechanical structure of the base material.

Easy to Use

• Simple Operation

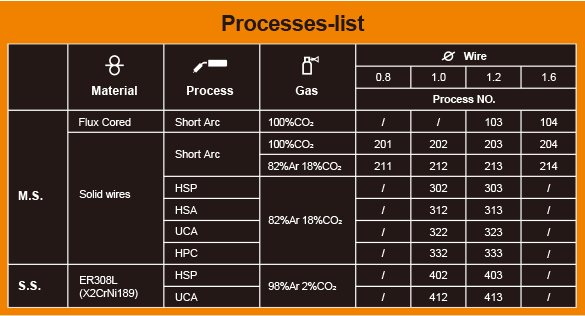

3 Steps To Achieve Weld Perfection

① Select operation mode.

② Select Processes-list No. (Welding process)

③ Adjust welding current.

(always the perfect setting by the synergic function using the material thickness)

Synergy Control With Processes-list

The Processes-list display is easily and intuitively controlled through its graphical user interface. We assem bled the perfect welding curve in every Process-No. to help the users choose the best welding process for carbon steels, aluminum alloys and stainless steel. Operation is easier than ever before.

• Memory storage function

Users will have a variety of welding needs and hope to set the most suitable welding parameters for different materials and workpieces. Steelmate PRO Series has memory storage function, up to 999 independent welding tasks (Jobs) to maintain/save different welding operation parameters. Select and quickly restore previous settings with one click, making operation simpler and more efficient.

• Flexible Control Methods

You can regulate the machine at the standard wire feeder, the optional remote control or the digital torch.

Optional Compact Wire Feeder with Detachable Control Panel

• Lighter and compact wire feeder is easy and convenient to be carried around in heady-duty working environments;

• Super durability comes from enhanced protective design;

• Simply operate the machine and set the parameters on the full-function wire feeder control panel;

• Detachable remote control on the wire feeder, all operations are in hand.

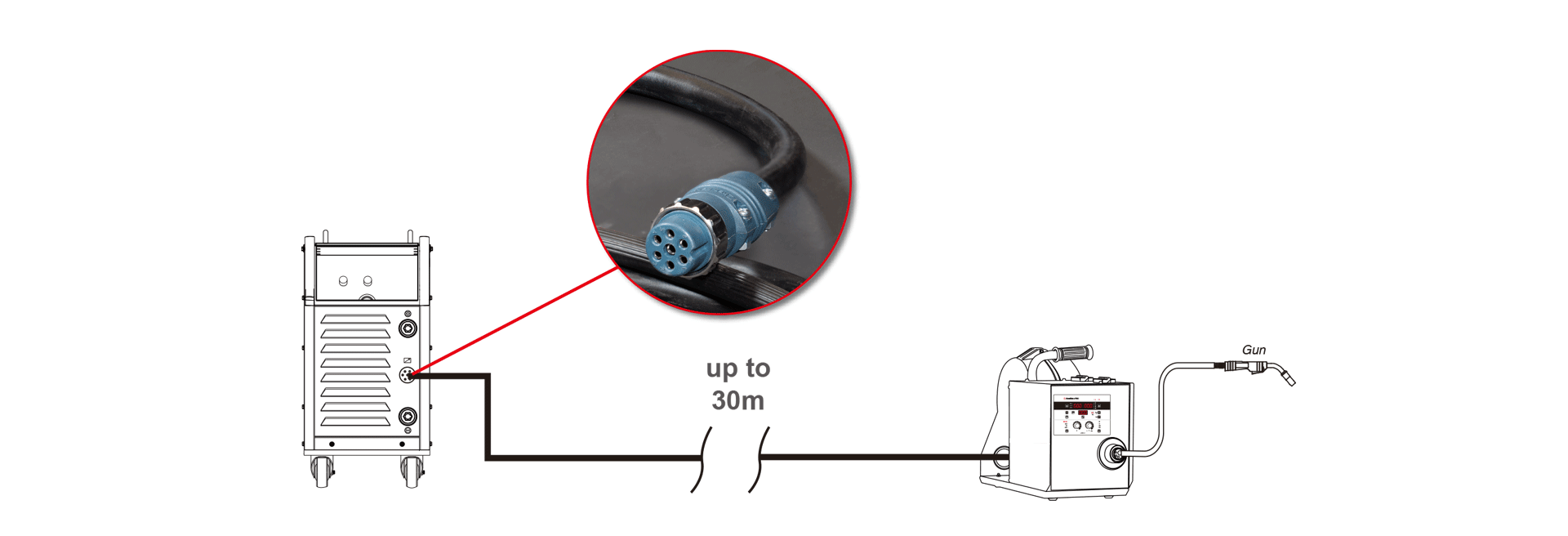

Ultra-long Distance Welding with Precise and Stable Arc Control

• Ultra-long Cable Loop Compensation

Regardless of working distance and long cable loop (up to 30 meters), the Steelmate Pro series maintains its high stability and performance thanks to the intelligent compensation function.

• Reliable and Durable Intermediate Cable Kit

The Intermediate cable kit (7 Pins only) connecting the main machine and the wire feeder is wrapped in thick rubber, which not only meets the needs for efficient communication, allowing for more precise control, but also helps reduce the occurrence of malfunctions.

Ready for Intelligent Fabrication

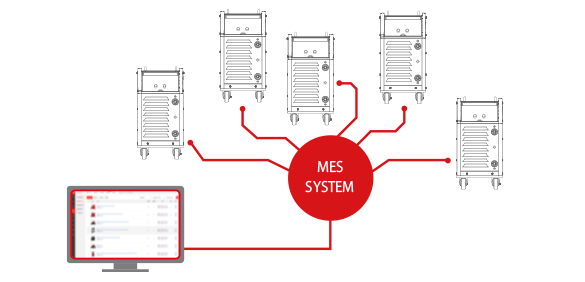

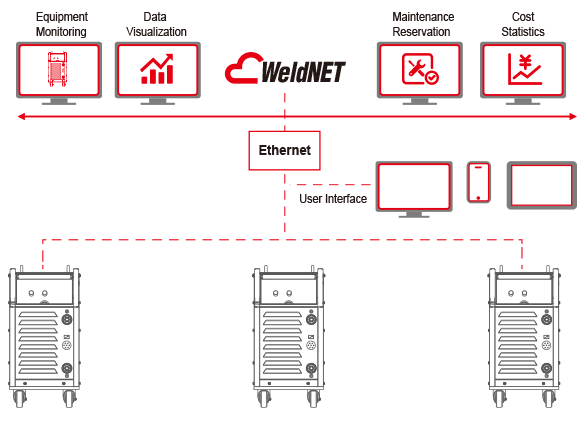

• MES and WeldNET Accessible

Steelmate PRO series is equipped with active user management and assigned NFC keys to set protection and permissions for parameter adjustment. It can also choose to connect to the MES system, which is more suitable for modern production data management.

By connecting to Topwell WeldNET, you can pre-control the parameters, monitoring the process at real time, and trace the quality, thanks to the equipment, production, and process management modules. Meanwhile, your productivity and quality are boosted with analytic and statistical tools. It unleashes the potential of your future welding production.

• Robot Welding Accessible

Robot interfaces are inserted via digital port (EtherNetlP, DeviceNet, CAN, CANOPEN, RJ485,etc.) with built-in communication protocols. No additional external communication modules are needed.

VIDEO

SPECIFICATIONS

|

Product Name

|

STEELMATE PRO350 | STEELMATE PRO500 |

|

Mains voltage(V) |

3PH~400V±15%(50/60Hz) | 3PH~400V±15%(50/60Hz) |

|

Max.Load Power Capacity |

18.1KVA | 25.83KVA |

Output Range | MIG: 30A/15.5V~350A/31.5V | MIG: 30A/15.5V~500A/39V |

Rated Duty cycle at 40℃ (105℉): 60% | MIG: 350A/31.5V | MIG: 500A/39V |

100% | MIG: 250A/26.5V | MIG: 400A/31.5V |

Open Circuit Voltage | 70V~80V | 70V~80V |

Power Factor | 0.87 | 0.87 |

Efficiency | 89% | 89% |

Wire feed unit | 4 rollers | 4 rollers |

Wire feed speed range | 0~25m/min | 0~25m/min |

Wire SpoolCapacity | 300mm(15~20kg) | 300mm(15~20kg) |

Wires φ (mm): Fe | 0.8~1.2mm | 0.8~1.6mm |

Flux-cored | 1.0~1.2mm | 1.0~1.6mm |

Dimension (L x W x H): Machine | 655 x 300 x 620 mm | 655 x 300 x 620 mm |

Wire feeder | 670 x 250 x 420mm

| 670 x 250 x 420mm

|

Net Weight : Machine | 45kg | 50kg |

Wire feeder | 15kg | 15kg |

YOU MAY ALSO NEED