Long Distance Welder Double Pulse MIG Welding Machine STEELMATE SL500 with Fewer Cables for Steel Welding

- Model

- STEELMATE SL500

Item specifics

- Mains voltage(V)

- 3PH~400V±15%(50/60Hz)

- Max.Load Power Capacity

- 25.18KVA

- Output Range

- 30A/15.5V~500A/39V

- Rated Duty cycle at 40℃(105℉): 60%

- 500A/39V

Review

Description

DETAILS

STEELMATE SL500

FULL CONTROL. FEWER CABLES.

Quick Specs

|

Steelmate po Series

|

Steelmate SL500 |

|

Input Voltage

|

3PH ~ 400V ±15% |

|

Rated Output(40℃) 60% |

500A/39V |

Cooling system | Air-cooled |

Gas | CO2/MAG |

Equipment

|

Welding process

|

|

|

Solid wires (GMAW)

|

●

|

Flux-cored (FCAW) | ● |

Metal-cored (MCAW) | ● |

Air carbon arc cutting & gouging (CAC-A) | ● |

Stick (SMAW) | ● |

● Standard ○Optional

The advantage of the P-L-C technology

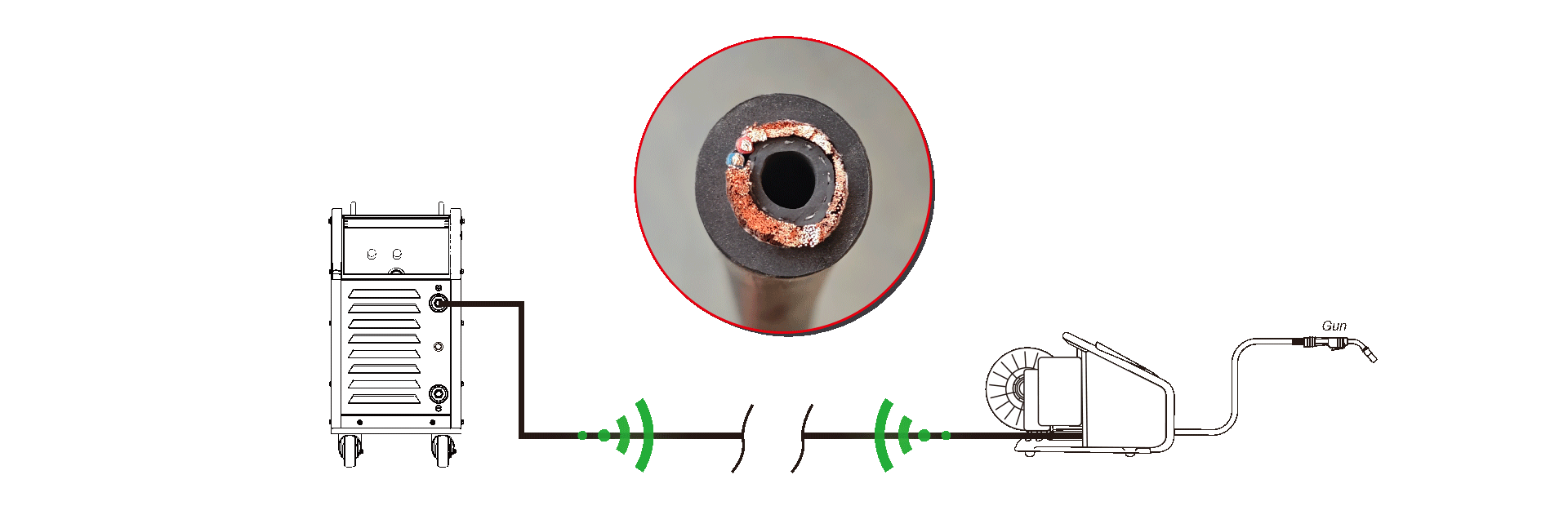

The Power Line Communication (PLC) is one kind of the Carrier Communication technologies that taken by the Topwell's special designed welding cable (Coaxial cable with built-in gas hose), can get a great advantage for the ultra-long welding applications (especially the ship building or steel constructions).

The key techno points of the Topwell's PLC system:

• Two-Way Carrier Communication makes precise welding controls;

• Dual-Band Carrier Control makes strong anti-interference ability;

Benefits:

Eliminate the extra cables

• Less jobsite clutter;

• Greater safety;

• Significantly weight loss for ultra-long-distance cables;

Ultra-long-distance welding with precise & stable arc controls

• Full functional remote controller at hand;

• By the Ultra-long loop compensation system, it makes the arc voltage greater precise & stable;

Excellent welding performance

• Optimized for all solid or flux-cored wires;

• Capable for metal-cored wires;

• Great result of vertical-up welding for thin plates: small seam and well formed.

Capable for future intelligent fabrication

Optional user management

Steelmate SL series is equipped with active user management and assigned NFC keys to set protection and permissions for parameter adjustment.

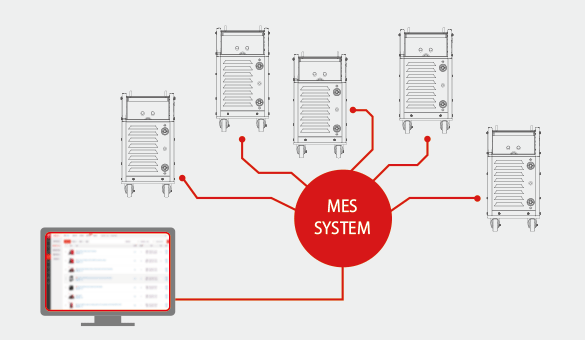

MES system

It can also choose to connect to the MES system, which is more suitable for modern production data management.

Optimized wire feeder

• 30% lighter than regular feeding mechanism;

• Greater reliability comes from enhanced protective design;

• Simple operation by the digital controller with full functions;

Innovative intermediate junction box

• Great help of the maintenance in case of the coaxial cable damage;

• The intermediate cable could be simply extended up to 100 meters by the junction box as required.

Complete protections make the machine more reliable

• Short circuit protection of the carrier communication loop;

• Adapt to harsh working environment typically in shipbuilding & offshore engineering;

• System protections from over-heated, over/less power loading …

SPECIFICATIONS

|

Product Name

|

STEELMATE SL500 |

|

Mains voltage(V) |

3PH~400V±15%(50/60Hz) |

|

Max.Load Power Capacity |

25.18KVA |

Output Range | MIG: 30A/15.5V~500A/39V |

Rated Duty cycle at 40℃(105℉): 100% | MIG: 500A/39V |

Open Circuit Voltage | 70V~80V |

Power Factor | 0.87 |

Efficiency | 89% |

Wire feed unit | 4 rollers |

Wire feed speed range | 0~25m/min |

Wire SpoolCapacity | 300mm(15~20kg) |

Wires φ (mm): Fe | 0.8~1.6mm |

Alu | 1.0~1.2mm |

Flux-cored | 1.0~1.6mm |

Dimension (L x W x H): Machine | 655 x 300 x 620 mm |

Wire feeder | 500 x 210 x 400 mm |

Net Weight : Machine | 50kg |

Wire feeder | 12kg |

YOU MAY ALSO NEED